It is key for medical equipment to have reliable connectivity and accurate signal transmission performance, so when selecting connectors for the medical field, multiple issues need to be considered to ensure that the connectors achieve the highest performance and reliability within the expected service life of the medical equipment. This article mainly shares the selection of connectors for the medical field.

As epidemic prevention enters the normalization, the demand for masks and epidemic prevention and disinfection will remain at a high level for a long time. At present, wearing masks and disinfecting public places are considered to be one of the most effective and economical means under normalized epidemic prevention, and are widely advocated and implemented. In this context, equipment such as mask machines and intelligent disinfection robots will bear more scientific and technological support in the protracted war against the epidemic.

Medical Equipment Wire Harness for Stable Operation in Cochlear Device |

Wire Harnesses and Cable Assemblies Make Medical Devices Last |

Customized Electronic Medical Equipment Cable Wire Harness Connector Application |

The differences in equipment application scenarios lead to different performance considerations in the selection of connectors. Below we analyze the focus of mask machines and intelligent disinfection robots in the selection of connectors by example:

1. The focus of the mask machine in selecting connectors: vibration resistance and impact resistance

The mask machine adopts PLC automatic control, and controls the motor movement by outputting control signals to achieve a series of operations. During the operation of the mask machine, the biggest external test faced by its connector is the external force of vibration and impact of the workshop and the equipment itself. This will test the strength of the connector body and the firmness of the connection lock. Therefore, when selecting signal connectors for mask machines, the focus should be on the vibration and impact resistance of the connector.

The focus of the selection of connectors for intelligent disinfection robots: protection performance and corrosion resistance

The intelligent disinfection robot is a mobile robot that uses ultrasonic spray disinfection. It can realize a variety of intelligent disinfection modes such as autonomous planning of paths, regional disinfection, and customized duration. Its own complexity determines that various power, signal and data connectors will be used. During the disinfection operation of the intelligent disinfection robot, the biggest test faced by its connector is the corrosion effect of the disinfectant spray on the connector. The strong corrosiveness of the disinfectant itself will corrode the shell of the connector, affecting its strength and destroying the protective effect of the shell on the internal components of the connector. Therefore, when selecting connectors for intelligent disinfection robots, the focus should be on the protection level and corrosion resistance of the connector.

1. YM has high vibration and impact resistance, and is suitable for the high-amplitude vibration and impact of mask machine equipment

Internal structure diagram of YM industrial connector

YM industrial connector is made of high-performance outdoor engineering plastic material, with higher mechanical strength and better pressure resistance. At the same time, it adopts the bayonet connection method and three-point locking structure design, which has high vibration and impact resistance, and can fully adapt to the continuous high-amplitude vibration and impact generated by the high-speed operation of the mask machine and other power equipment in the workshop. Ensure that the connector is more securely connected in the above-mentioned use environment, and there will be no destructive damage, looseness or falling off.

2. YM has high protection and high corrosion resistance, and is suitable for disinfection robots

YM series industrial connectors have high protection performance. It adopts a full range of strict protection structure design, and the socket and box, plug and socket, plug and cable are all sealed, so that it can reach the highest protection level of IP68. It can resist the risk of water and disinfectant invading the connector in the working environment.

YM industrial connector has high corrosion resistance. Its shell is made of high-performance outdoor engineering plastic, and the internal terminal adopts nickel-bottom gold-plated surface treatment process. And through the neutral salt spray NSS test, it has super salt spray corrosion resistance, which can resist the corrosion of disinfectant and other liquids on the disinfection robot connector.

Of course, if the equipment pays more attention to the convenience of connector operation, then the LP series connector products of Lingke are recommended. It adopts a spring snap-on locking connection method, which can be operated with one hand and plugged and unplugged with one button, making the operation faster and more convenient. فضلاً عن ذلك, LP is also built with industrial-grade waterproof standards, and the overall waterproof sealing structure design is adopted, with a maximum protection level of IP68. At the same time, the shell is also made of high-performance outdoor engineering plastic material, which has a high level of salt spray corrosion resistance and can fully meet the technical requirements of medical equipment for connectors.

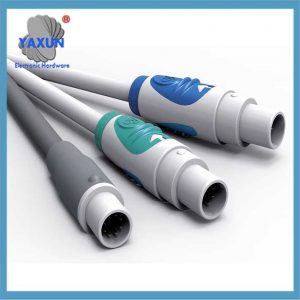

YAXUN Technology Co., المحدودة. is a technology-based company specializing in the sales of waterproof connectors and customized solution services. The company operates many products, including circular waterproof connectors (aviation plugs), airtight connectors, heavy-duty connectors, CEE/lEC60309 industrial waterproof plugs and sockets, distribution boxes, wiring harnesses, إلخ. The company’s products are mainly used in LED display screens, stage lighting, new energy, security equipment, industrial automation equipment, communication equipment, audio-visual equipment, LED lighting, medical, aviation, automobile, rail transportation, shipbuilding, photovoltaic wind energy and other fields, and have accumulated rich practical experience. It also has cooperative brands such as CNLINKO, WEIPU, E-Weichat and other industry-leading factories. Its products have various domestic and foreign certifications, meeting the environmental protection and quality requirements of the domestic and foreign markets.

Medical Equipment Field with ISO 13485 Certs Wiring Harness |

Customized Electronic Medical Equipment Cable Wire Harness Equivocal Connector Application |

Disposable and Limited-Use Medical Connector Products |

Key points to consider:

Safety features:

Push-pull design with audible click: Ensures proper engagement and prevents accidental disconnection.

Color coding: Helps differentiate between different signal types and prevent misconnections.

Unique mechanical coding: Prevents incompatible connectors from mating.

Insulation design: Protects against potential shock hazards.

Electrical characteristics:

Low signal level compatibility: Choose connectors designed for handling small signal amplitudes like those found in ECG monitoring.

Shielding: Consider shielded connectors to minimize electromagnetic interference (EMI).

Current rating: Select connectors with appropriate current carrying capacity for the power requirements.

Durability and mating cycles:

High-quality materials: Opt for robust materials that can withstand repeated mating cycles.

Contact design: Ensure reliable contact with good gold plating for corrosion resistance.

Mating force: Choose a connector with appropriate mating force for easy connection and disconnection while wearing gloves.

Sterilization compatibility:

Material selection: Select materials that can withstand the intended sterilization method (e.g., autoclave, ethylene oxide).

Sealing design: Consider connectors with seals to prevent fluid ingress during sterilization.

Application-specific considerations:

Operating environment: Choose connectors suitable for the expected temperature and humidity conditions.

Size constraints: Select connectors that fit within the available space on the medical device.

Signal type: Consider the type of signals being transmitted (analog, digital, mixed) and choose connectors with appropriate contact configurations.

Common connector types used in medical devices:

Circular connectors: Often used for high-density applications due to their compact design and ability to accommodate multiple signals.

D-sub connectors: Commonly seen in older medical equipment, but can be bulky and may not offer the best signal integrity.

Push-pull connectors: Preferred for their ease of use and secure connection.

Micro connectors: Suitable for small, portable devices and delicate applications.

English

English العربية

العربية Български

Български Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska Tiếng Việt

Tiếng Việt